-

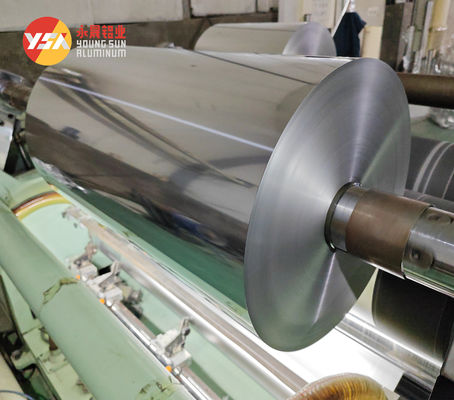

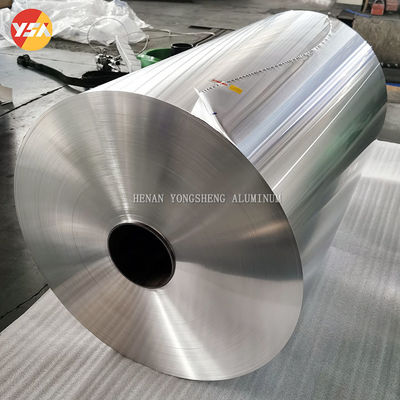

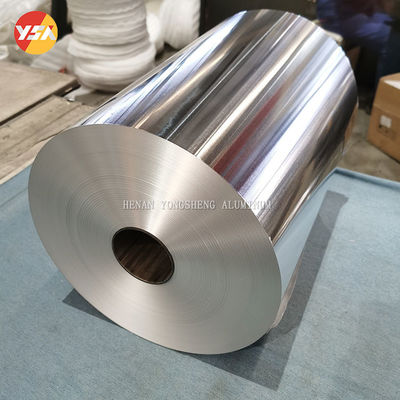

Bobina de tira de aluminio

-

Bobina de aluminio revestida del color

-

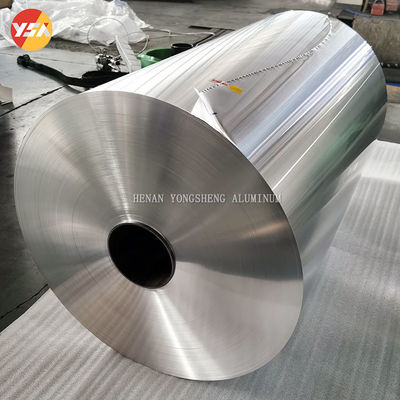

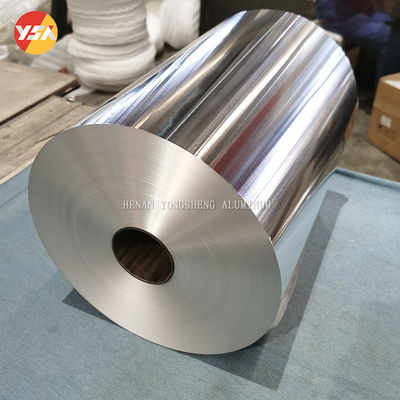

Rollo del papel de aluminio

-

Placa de aluminio

-

Disco de aluminio del círculo

-

Película de poliéster laminada con papel de aluminio

-

Placa a cuadros de aluminio

-

Diamond Plate Sheet de aluminio

-

Hoja de aluminio grabada en relieve

-

Hoja de aluminio anodizada

-

Hoja de aluminio del espejo

-

Contenedor de papel de aluminio

-

Fiambrera del papel de aluminio

-

Grill de barbacoa desechable

-

MartinLa primera vez que cooperamos con el aluminio de Yongsheng, lo encontramos muy fácil, porque plazo de expedición de las mercancías era muy rápido, y el director empresarial era también muy profesional. Él me ayudó a solucionar algunos problemas técnicos. ¡Las mercancías fueron recibidas en 2021.1.20 y la calidad de las mercancías muy buenas!

MartinLa primera vez que cooperamos con el aluminio de Yongsheng, lo encontramos muy fácil, porque plazo de expedición de las mercancías era muy rápido, y el director empresarial era también muy profesional. Él me ayudó a solucionar algunos problemas técnicos. ¡Las mercancías fueron recibidas en 2021.1.20 y la calidad de las mercancías muy buenas! -

Alice SuNuestra compañía y aluminio de Yongsheng han estado cooperando por casi tres años. Hemos visitado la fábrica, Yongsheng es un proveedor material de aluminio profesional, hemos estado comprando las tiras de aluminio en su fábrica, y mantendremos la cooperación a largo plazo.

Alice SuNuestra compañía y aluminio de Yongsheng han estado cooperando por casi tres años. Hemos visitado la fábrica, Yongsheng es un proveedor material de aluminio profesional, hemos estado comprando las tiras de aluminio en su fábrica, y mantendremos la cooperación a largo plazo. -

ZoeyCompramos el círculo de aluminio del aluminio de Yongsheng y los enviamos a Ghana. Hemos mantenido una relación tan cooperativa por dos años, y tenemos que enviar cada mes. En curso de cooperación, cada vínculo es muy eficiente, y el administrador de cuentas nos ayudará a solucionar problemas rápidamente. Somos muy felices de encontrar a un proveedor confiable.

ZoeyCompramos el círculo de aluminio del aluminio de Yongsheng y los enviamos a Ghana. Hemos mantenido una relación tan cooperativa por dos años, y tenemos que enviar cada mes. En curso de cooperación, cada vínculo es muy eficiente, y el administrador de cuentas nos ayudará a solucionar problemas rápidamente. Somos muy felices de encontrar a un proveedor confiable. -

Amin MazlumHemos comprado un total de casi 500 toneladas de bobinas de aluminio grabadas en relieve del color del aluminio de Yongsheng. La calidad ha sido estable y plazo de expedición es rápido. Satisfacen a mis clientes muy con mis productos. Continuaremos cooperando con el aluminio de Yongsheng.

Amin MazlumHemos comprado un total de casi 500 toneladas de bobinas de aluminio grabadas en relieve del color del aluminio de Yongsheng. La calidad ha sido estable y plazo de expedición es rápido. Satisfacen a mis clientes muy con mis productos. Continuaremos cooperando con el aluminio de Yongsheng.

0.012-0.1mm 3003 H13 Fuel de aluminio para papel de panal

| Lugar de origen | Provincia de Henan, China |

|---|---|

| Nombre de la marca | Henan Yongsheng |

| Certificación | ISO, RoHS |

| Número de modelo | Fuel de pan de miel |

| Cantidad de orden mínima | 1 tonelada |

| Detalles de empaquetado | Embalaje estándar para uso marítimo |

| Tiempo de entrega | 7-25 días después de la confirmación del pedido |

| Condiciones de pago | El importe de la ayuda se calculará en función de la cantidad de productos que se hayan vendido. |

| Capacidad de la fuente | 5000 toneladas por mes |

| De aleación | 3003, etc. | Temperatura | H18, H19, etc. |

|---|---|---|---|

| Grosor | 0.012-0.1m m | Ancho | 180-1350 mm |

| longitud | Requisitos del cliente | Desempeño | Resistencia a la tracción> 240 MPa, alargamiento después de la ruptura> 1% |

| Puerto | Shanghai, Tianjin y Qingdao | Muestra | Gratis |

| Resaltar | rollo de papel de aluminio ultrafino,3003 H13 Hoja de panal de abejas,0.012 mm de lámina de aluminio |

||

| Atributo | Valor |

|---|---|

| Aleación | 3003, etc. |

| Temperamento | H18, H19, etc. |

| Espesor | 0.012-0.1 mm |

| Ancho | 180-1350 mm |

| Longitud | Requisito del cliente |

| Actuación | Resistencia a la tracción> 240 MPa, alargamiento después del descanso> 1% |

| Puerto | Shanghai, Tianjin, Qingdao |

| Muestra | Gratis |

0.012-0.1mm 3003 H13 Foil de aluminio para papel de panal

- Base de composición: aleación de aluminio-manganeso (MN aproximadamente 1.0-1.5%)

- Mecanismo de fortalecimiento: endurecimiento puro del trabajo en frío (fortalecimiento del tratamiento sin calor)

- Alta fuerza: nivel de alta fuerza logrado a través del trabajo en frío

- Alta dureza: alta dureza de la superficie y resistencia al desgaste relativamente buena

- Baja ductilidad: mala plasticidad y formabilidad limitada. No es adecuado para operaciones de formación drástica como dibujo profundo

- Mantener una buena resistencia a la corrosión: excelente resistencia a la corrosión en el entorno atmosférico y muchos entornos químicos

- Buena soldadura: pero la zona de soldadura afectada por el calor se ablandará (disminución de la resistencia)

- Buena procesabilidad: se puede procesar, pero se necesitan más herramientas que el estado blando

El procesamiento de aluminio en el núcleo de panal es un proceso preciso y altamente automatizado. El núcleo es formar una estructura de células de panal hexagonal continua a través de un proceso especial de formación y unión.

Seleccione bobinas de aluminio de aluminio de grado 3003 específico y espesor. La superficie de aluminio de aluminio debe sergrada y tratada químicamente (como croming o tratamiento sin cromo) para mejorar la adhesión de los adhesivos posteriores.

Aplique adhesivo de alta resistencia en rayas paralelas a ubicaciones específicas en la lámina de aluminio. El ancho y el espacio de las rayas de pegamento determinan el tamaño y la forma de las células finales de panal. Método de pegado: recubrimiento o pulverización del rodillo de precisión para garantizar que la línea de pegamento sea uniforme, continua y posicionada con precisión.

La lámina de aluminio pegada pasará a través de un conjunto de rodillos de corrugación de precisión. Estos rodillos presionan la lámina de aluminio originalmente plana en una forma de onda continua. La distancia máxima y la altura de la corrugación deben coincidir estrictamente con el espacio de las rayas de pegamento.

Alinear y apilar con precisión (generalmente docenas de cientos de capas) de lámina de aluminio corrugado prensado. Punto clave: los picos de cada capa de aluminio de aluminio corrugado deben estar alineados con precisión con la posición de las rayas de pegamento de la capa adyacente.

La prensa caliente o el cinturón de prensa caliente continua aplican presión y calor al laminado. El adhesivo se derrite, fluye y se solidifica, uniendo firmemente los puntos de contacto de las láminas de aluminio corrugadas adyacentes. Después del curado, se forman puntos de enlace entre las capas de aluminio adyacentes en el recubrimiento de pegamento, y las partes corrugadas no recubiertas se abren naturalmente para formar el prototipo de las células de panal.

Después de la laminación y el curado, el papel de aluminio corrugado de múltiples capas originalmente separado se convierte en un bloque de aluminio integral con una estructura de poro regular en el interior, llamada "pila de panal" o "núcleo de panal" en blanco ". En este momento, las células de panal están conectadas en la dirección perpendicular al plano de la lámina de aluminio, pero las celdas a lo largo del plano de la lámina de aluminio aún no se han abierto completamente.

Arregle los dos extremos de la pila de panal curada en la máquina de estiramiento. Aplicar tensión perpendicular a la dirección de corrugación. Bajo la acción de la tensión, los puntos de enlace entre las capas de aluminio de aluminio corrugado sirven como puntos fijos. Los canales de las corrugaciones se separan, y las estructuras celulares apiladas originalmente se extienden uniformemente como un acordeón. Finalmente, se forma una estructura de panal tridimensional con células celulares hexagonales regulares, continuas y continuas. La velocidad y la resistencia de estiramiento deben controlarse con precisión para garantizar que las células celulares se abran uniformemente, sin desgarro o deformación.

| Aleación | 3003, etc. |

| Temperamento | H18, H19, etc. |

| Espesor | 0.012-0.1 mm |

| Ancho | 180-1350 mm (tolerancia: ± 1.0 mm) |

| Longitud | Según sus requisitos |

| Característica | Ecológico |

| Paquete | Embalaje estándar para el mar |

| Tipo | Bobina de aluminio de aluminio de alta pureza |

| Color | Plata |

| Forma | Alu bobina |

| Dureza | O/Ho |

| Conductividad (% IACS) | ≥61.5 |

| Alargamiento (%) | > 23 |

| Solicitud | Industria, decoración, construcción, embalaje, apremiante, etc. |

| Tratamiento superficial | Acabado del molino, recubierto, polvo recubierto, anodizado, espejo pulido, en relieve, etc. |