Todos los productos

-

Bobina de tira de aluminio

-

Bobina de aluminio revestida del color

-

Rollo del papel de aluminio

-

Placa de aluminio

-

Disco de aluminio del círculo

-

Película de poliéster laminada con papel de aluminio

-

Placa a cuadros de aluminio

-

Diamond Plate Sheet de aluminio

-

Hoja de aluminio grabada en relieve

-

Hoja de aluminio anodizada

-

Hoja de aluminio del espejo

-

Contenedor de papel de aluminio

-

Fiambrera del papel de aluminio

-

Grill de barbacoa desechable

-

MartinLa primera vez que cooperamos con el aluminio de Yongsheng, lo encontramos muy fácil, porque plazo de expedición de las mercancías era muy rápido, y el director empresarial era también muy profesional. Él me ayudó a solucionar algunos problemas técnicos. ¡Las mercancías fueron recibidas en 2021.1.20 y la calidad de las mercancías muy buenas!

MartinLa primera vez que cooperamos con el aluminio de Yongsheng, lo encontramos muy fácil, porque plazo de expedición de las mercancías era muy rápido, y el director empresarial era también muy profesional. Él me ayudó a solucionar algunos problemas técnicos. ¡Las mercancías fueron recibidas en 2021.1.20 y la calidad de las mercancías muy buenas! -

Alice SuNuestra compañía y aluminio de Yongsheng han estado cooperando por casi tres años. Hemos visitado la fábrica, Yongsheng es un proveedor material de aluminio profesional, hemos estado comprando las tiras de aluminio en su fábrica, y mantendremos la cooperación a largo plazo.

Alice SuNuestra compañía y aluminio de Yongsheng han estado cooperando por casi tres años. Hemos visitado la fábrica, Yongsheng es un proveedor material de aluminio profesional, hemos estado comprando las tiras de aluminio en su fábrica, y mantendremos la cooperación a largo plazo. -

ZoeyCompramos el círculo de aluminio del aluminio de Yongsheng y los enviamos a Ghana. Hemos mantenido una relación tan cooperativa por dos años, y tenemos que enviar cada mes. En curso de cooperación, cada vínculo es muy eficiente, y el administrador de cuentas nos ayudará a solucionar problemas rápidamente. Somos muy felices de encontrar a un proveedor confiable.

ZoeyCompramos el círculo de aluminio del aluminio de Yongsheng y los enviamos a Ghana. Hemos mantenido una relación tan cooperativa por dos años, y tenemos que enviar cada mes. En curso de cooperación, cada vínculo es muy eficiente, y el administrador de cuentas nos ayudará a solucionar problemas rápidamente. Somos muy felices de encontrar a un proveedor confiable. -

Amin MazlumHemos comprado un total de casi 500 toneladas de bobinas de aluminio grabadas en relieve del color del aluminio de Yongsheng. La calidad ha sido estable y plazo de expedición es rápido. Satisfacen a mis clientes muy con mis productos. Continuaremos cooperando con el aluminio de Yongsheng.

Amin MazlumHemos comprado un total de casi 500 toneladas de bobinas de aluminio grabadas en relieve del color del aluminio de Yongsheng. La calidad ha sido estable y plazo de expedición es rápido. Satisfacen a mis clientes muy con mis productos. Continuaremos cooperando con el aluminio de Yongsheng.

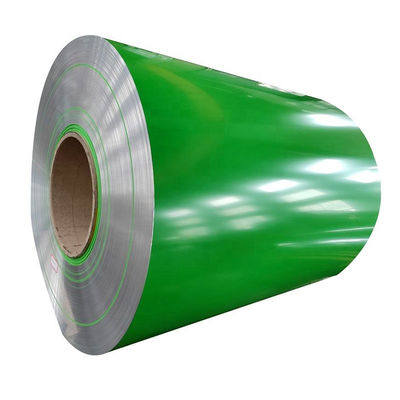

Rollo de bobina de aluminio con revestimiento de PVC PE de la serie 3000, chapa de aluminio pintada

| Lugar de origen | Provincia de Henan, China |

|---|---|

| Nombre de la marca | YONGSHENG |

| Certificación | SO,RoHS,MSDS,MTC |

| Número de modelo | Serie 1000 3000 |

| Cantidad de orden mínima | 5 toneladas |

| Precio | 2950-3150 USD/Ton |

| Detalles de empaquetado | Embalaje estándar para el mar |

| Tiempo de entrega | 7-25 días después de la confirmación del pedido |

| Condiciones de pago | L/C, D/A, D/P, T/T |

| Capacidad de la fuente | 5000 toneladas por mes |

Datos del producto

| Aleación | 1050, 1060, 1100, 3003, 3004, 3105, etc. | Temperamento | O-H112 |

|---|---|---|---|

| Espesor | 0.2-3 mm | Ancho | 10 mm-1600 mm, se puede dividir en tiras |

| Tolerancia | ± 1% | Tratamiento superficial | Capa de PVDF, PE cubriendo el etc. |

| Espesor de revestimiento | PE≥18 μm, PVDF≥25 μm | Color | Plata, bronce, negro, dorado, azul, gris, brillante, etc. |

| Embalaje | Exportación de madera de exportación de madera | Muestra | gratis |

| Resaltar | bobina de recubrimiento de aluminio recubierta de PVC,rollo de chapa de aluminio pintada,Bobina de aluminio recubierta de color |

||

Descripción de producto

Bobina de aluminio con revestimiento de PVC PE de la serie 3000, lámina de aluminio pintada

Láminas de aluminio recubiertas de alto rendimiento diseñadas para aplicaciones industriales y arquitectónicas con resistencia superior a la intemperie y durabilidad.

Especificaciones del producto

| Aleación | Espesor (mm) | Espesor del recubrimiento (micras) | Ancho (mm) | Temple |

|---|---|---|---|---|

| A1050,A1060,A1070,A1100,A1235,A1245 | 0.15-3.0 | PE≥14 PVDF≥25 | 20-2200 | O,H12,H22,H14,H24,H16,H26,H18 |

| 3.0-12.0 | - | 20-2200 | H111,H112 | |

| A3003,A3004,A3105 | 0.2-4.0 | - | 20-2200 | O,H12,H22,H14,H24,H16,H26,H18 |

| 4.0-12.0 | - | 20-2200 | H111,H112 | |

| A5052,A5083,A5754,A5005 | 0.2-4.0 | - | 20-2200 | O,H12,H22,H14,H24,H16,H26,H18 |

| 4.0-12.0 | - | 20-2200 | H111,H112 | |

| A6061,A6082,A6063 | 0.15-12 | - | 20-2200 | T6,T4,T651 |

| A8011,1235 | 0.006-0.2 | - | 20-2200 | O,H14,H18,H24 |

Acabado del recubrimiento: PVDF (Fluoruro de polivinilideno), PE (Poliéster)

Dureza del recubrimiento: Más de HB (resistencia al lápiz)

Ventajas clave

- Resistente a altas temperaturas

- Resistente a la intemperie

- Resistente al frote

- Aislamiento acústico

- A prueba de ácidos o álcalis

- A prueba de fuego

- Material ligero para una fácil construcción e instalación

ID: 405MM, 505mm

Embalaje: Palés de madera de exportación, caja de madera

Estándares: ASTM-B209, EN573-1, GB/T3880.1-2006

Comparación de aluminio recubierto de PE vs. PVC

Las láminas de aluminio recubiertas de PE y las láminas de aluminio recubiertas de PVC pertenecen a las láminas de aluminio recubiertas en la superficie con una lámina de aleación de aluminio como material base central. Las diferencias clave residen en los materiales de recubrimiento.

Lámina de aluminio recubierta de PE

Ventajas clave:

- Excelente resistencia a la intemperie y a la corrosión para entornos exteriores y agresivos

- Buena flexibilidad y fuerte adaptabilidad de procesamiento para requisitos de forma compleja

- Alta estabilidad a largo plazo con bajo costo de mantenimiento

- Respetuoso con el medio ambiente, adecuado tanto para uso en interiores como en exteriores

Principales desventajas:

- Menor dureza superficial y resistencia al rayado

- La textura decorativa carece de efecto tridimensional

- Mayor costo de producción en comparación con el PVC

Bobina de aluminio recubierta de PVC

Ventajas clave:

- Alta dureza superficial y excelente resistencia al rayado

- Fuerte textura tridimensional con colores vivos para un efecto decorativo mejorado

- Menor costo de producción con un proceso de recubrimiento simple

Principales desventajas:

- Poca resistencia a la intemperie y menor vida útil en exteriores

- Flexibilidad y capacidades de procesamiento limitadas

- Poca resistencia al calor, inadecuado para entornos de alta temperatura

- Posible liberación de sustancias nocivas, que requiere pruebas ambientales

Recomendaciones de compra

- Uso a largo plazo en exteriores (paredes exteriores, anuncios exteriores): Elija láminas de aluminio recubiertas de PE con recubrimiento resistente a la intemperie

- Decoración de interiores con presupuesto limitado (armarios, vitrinas): Considere las láminas de aluminio recubiertas de PVC con informe de pruebas ambientales (RoHS, GB 18585)

- Requisitos de procesamiento complejos (flexión, estampado): Debe elegir láminas de aluminio recubiertas de PE (el PVC es propenso a agrietarse)

- Entornos de alta temperatura (cocinas, fuentes de calor): PVC estrictamente prohibido; PE recomendado

Guías de mantenimiento

Lámina de aluminio recubierta de PE

- Limpiar con agua o limpiador neutro

- Evite los cepillos de cerdas duras para evitar rayones

- Uso en exteriores: Limpiar cada 1-2 años para prolongar la vida útil

Lámina de aluminio recubierta de PVC

- Evite el contacto con altas temperaturas (agua caliente, hornos)

- Limpiar con un paño seco o un limpiador débilmente alcalino

- Evite los disolventes fuertes (gasolina, etc.)

- Uso en exteriores: Inspeccionar cada seis meses; reemplazar inmediatamente si el recubrimiento se agrieta

Imágenes del producto

Aplicaciones del producto

Productos recomendados